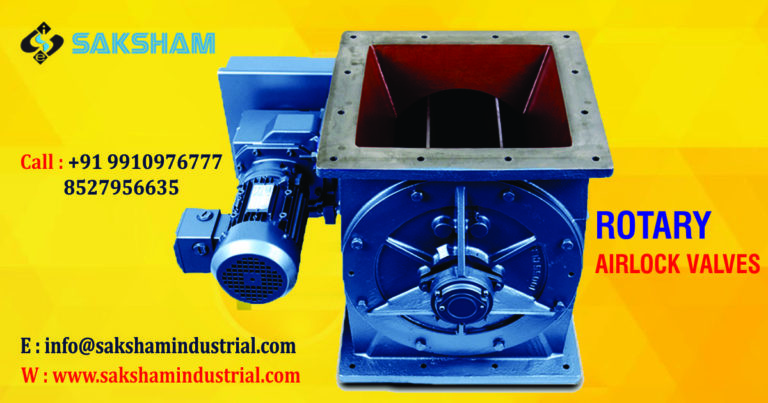

What are Rotary Airlock Valves and its advantages?

Rotary Airlock Valves are also known as Rotary Feeders and rotary valves. This product is used for both vacuum style and pressure styles pneumatic conveying systems. The main work of these valves is to serve as a lock that prevents loss of air whereas it also performs a vital product that handles various other functions.

In other and simple words, these rotary feeders are an essential component for the efficiency of a conveying system. It is vital to understand that not all rotary valves are inevitably rotary airlock valves but effectively all rotary airlocks are air valves.

Rotary valves are compact equipment that can offer a proscribed and unremitting release of coarse or powdery matter under gravity. These rotary feeders have a rotor that has pockets and organizes the nosh by changeable the filling ratio and rotor speed of pockets.

Rotary feeders have a broad range of functions and they came into work to control the flow of bulk substance and bout the material division.

Applications of Rotary Air Lock ValvesIt maintains airlock between a conveying line and mixer.

- It does bout the material from a silo to conveying line or weigh hopper.

- It helps in the smooth discharge of a product from the hopper.

- It maintains airlock a conveying line and a screw conveyor.

- It blows through rotary valves which are used to accurate pneumatic conveying.

Feature of Rotary Air Lock ValvesIt maintains a different pressure between outlet (airlock) and inlet.

- It is available in Blow through and drops through options.

- It controlled flow rate of products (variable or fixed).

- It produced in cast iron to provide better air locking and accuracy.

- This product is suitable for granular materials and powdery.

- It is available with suitable tips of application.

- It acts as a process isolator.

Rotary Air Lock Valves sectors Paint and putty plant

- Plastics

- Detergents

- Food processing

- Dry Premix and building Materials

- Chemicals

Rotary Feeders Models

There are numerous types of airlock models exist for various mass solids and application. Stream channel, storehouse, pneumatic transportation, transport, typhoon applications need an assorted kind of airlock valves. The kind of the mass strong (dampness, abrasion, hardness, temperature, flexibility and measurement) likewise indispensable to opt a correct type of airlock show.Products took care with the help of rotary feeders.

Coal dust, coal, PVC, sawdust, fly fiery remains, plastic pellets, marble powder, glass powder, salt zest, concrete, calcite slag, sugar, coffee powder, espresso grains, chestnut, oats, grains, cotton seeds, sunflower seeds, almond, shelled nuts, nuts, dried natural products, rice, sesame, soybean, pea, lentil, bean, chickpea, corn, seed, feed, waste, grain, rye, oat, flour and wheat.

The prime capacity of a rotary feeder is to handle the drip out of one cavity to another one whereas it also keeps all conditions of a decent airlock. The product is for the most part in granular shape or dry powder.