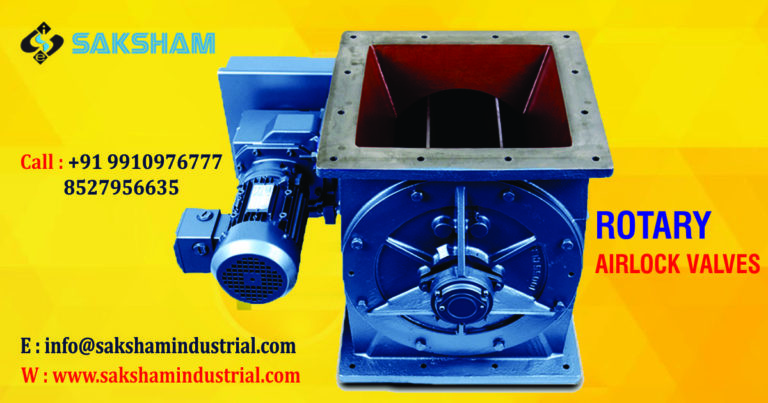

How Do Rotary Airlock Valves Work?

A Rotary Airlock Valve, also well-known as a rotary feeder or rotary valve, is a usually used part of forte or bulk material handling system in industrial & agricultural settings.

They are generally used in the release of solid material in bulk from hoppers or bins into a conveying system. These rotors are commonly determined by a small internal combustion engine or an electric motor and typically have huge metal vanes that are cast or weld on to it.

How Do They Work?

The Rotary Airlock Valves serve as a lock that prevents air loss while additionally performing different functions of handling materials. The metal vanes or blades on a rotary airlock rotate whereas it is in operation, and this makes a pocket between the blades.

The material that is handles by it enters these pockets through the inlet ports and exits by means of the outlet ports. In an airlock between the inlet port and outlet port, & airlock valve keeps some air sealed inside, permitting the material that is being handled to move downwards from the inlet port, into the valve, and afterward out through the outlet port.

The controlled air flow helps in keeping a constant air pressure between the ports which assist in moving the material though the ports. The maintenance of the air pressure is, accordingly, fundamental to the functioning of a rotary airlock valve.

Uses of Rotary Airlock Valves

Rotary Airlock Valves are found to be very useful in a wide variety of industrial and agricultural settings where dry and free-flowing solids, granules or powder for example cement, ore, sugar, grains etc are used. Rotary airlock valves are valuable useful in pollution control in an assortment of industries for example wood, paper, textile, tobacco and so on.

Components of a Rotary Airlock Valve

The components of a rotary airlock valve incorporate the rotor shaft which is the axis around which the entire system rotates, housing, head plates, packing seals and bearings, each of which serve explicit functions that empower the rotary feeder to perform its job. A Rotary Airlock Valve that is ordinary supported by bearings will be driven by an internal burning engine or an electric motor.

The Effects of Improper Airlocks

Rotary Airlocks are a vital part of various conveying systems. A Rotary Airlock Valves Manufacturer India would, there, suggest that the airlock valves be used correctly. Unnecessary wear and tear of the rotor, the housing or both will lead to airlock disappointment and will drive up the cost of maintenance.

When processing grating materials, care should be taken to reduce cumulative damage from the material particles being trapped in the vanes of the rotary airlocks valves. A typical reason for damage is when trapped materials produce surface drag scraped from being stuck in between planes that are moving in two unique directions.

Essentially, pneumatic surface abrasions are caused by turbulent air that gets accumulated at the outlet port and this can lead to severe loss of effectiveness and issues with material flow since this wayward air could carry abrasive materials with it that would cause harm to the valve.

Key Variables of Its Performance

The performance of a Rotary Airlock Valve depends on certain key variables for example the quantity of blades, the sort of rotors and the wear & abrasion of the rotary airlock valves.

The more the quantity of blades present, the more professional it will be in sealing the pressure difference between the inlet port & outlet port.

Hence, it can be concluded that choosing the correct kind of rotary airlock valve is imperative to get the maximum amount of efficiency.

Saksham Industrial is one of the leading Manufacturers & Exporters of Air – Gas, Material Handling and Air Pollution Control Equipment with a strong presence in India.

We design, develop and manufacture a variety of equipments. Quality is our main concern. Intended to be compact and tough, these equipments are incredibly economical and deliver high outputs at any given point of time. Our plants & machinery wants very low levels of maintenance. They can be custom developed according to the specifications given by the customers and deliver elevated levels of performance at any time.

Contact us today @ +91-9910976777 / +91-8527956635 to learn more about what makes Saksham Industrial one of the top rotary airlocks manufactures.