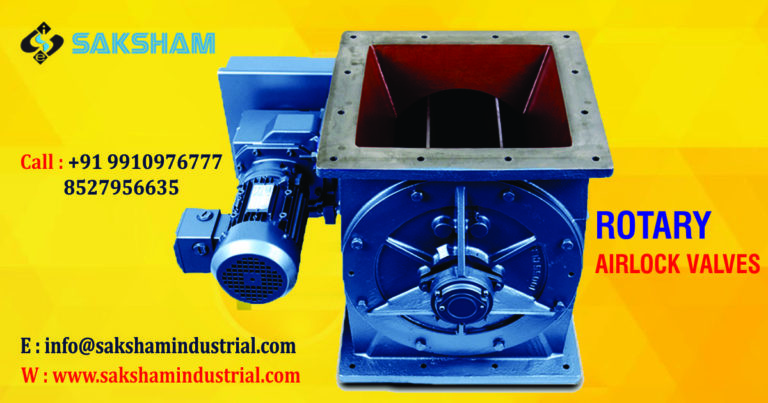

What are the features and design structure of Rotary Airlock Valve

As per some of the researches made, the main goal of a rotary airlock or the rotary valves is to regulate the current flow from one chamber to another. This movement takes place while maintaining a proper airlock condition. The product is primarily available in its granular or dry powder form.

The necessity behind a rotary valve:

A proper airlock remains important in any of the dust filtration fields on bag filter and cyclone applications. The Rotary Airlock Valve helps manufacturers to quote high dust collecting abilities and maintaining the same. Airlocks are proven to be quite effective in the pneumatic conveying industry as well. Here, the product gets regulated into a vacuum or pressure to convey line while minimizing the present air leakage.

Some companies provide an airlock valve without any double standards. All the items are machine-made with utmost precision for minimal eccentricities and close tolerances. These valves’ present norm will be 20 psi as extreme pressure, and the temperature can get up to 400 degrees Celsius. These are normal marks for accommodating special designs. For any additional application requirement, having a direct chat with the manufacturing team is important.

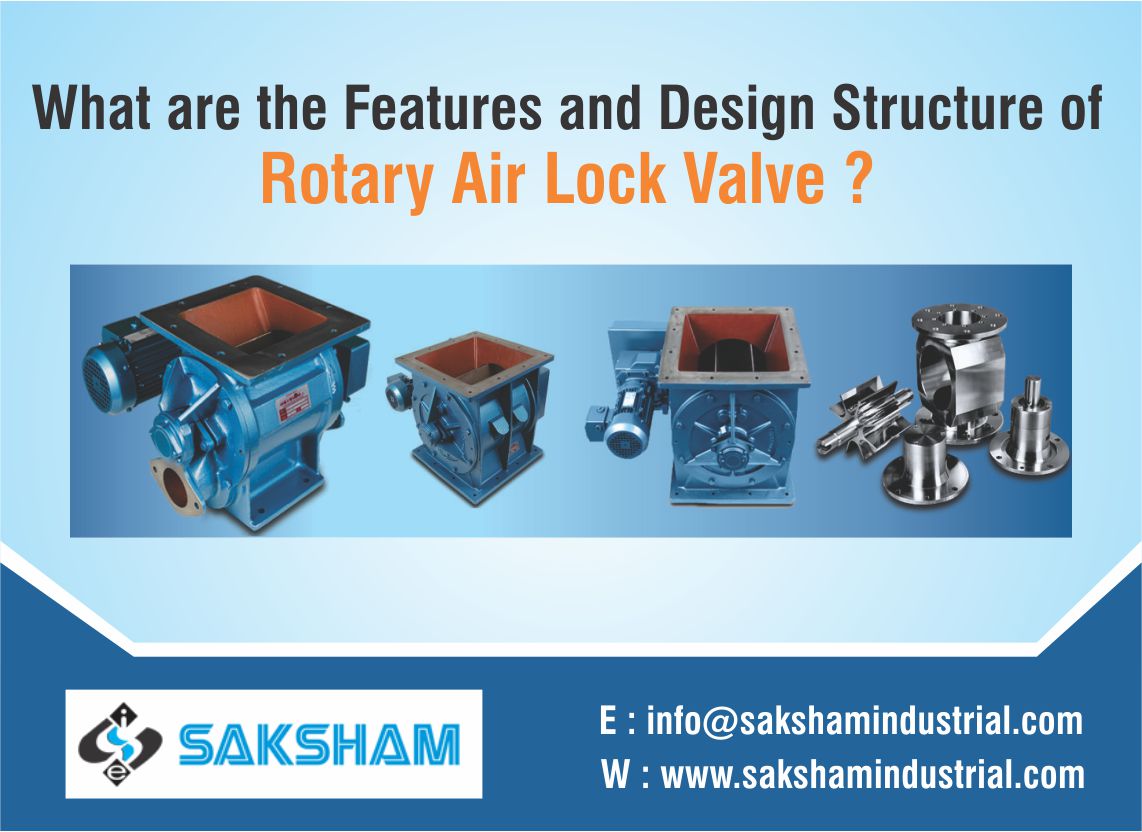

The design and construction:

The Rotary Airlock Valve is known for its heavy-duty based cast housing. It comprises two end covers and a body, one drive package, and one internal rotating rotor. The body consists of an outlet and inlet, allowing materials to enter and then exit from the valves.•

The rotor has a shaft with various vanes. The end of the shaft will further extend out through housing to some external bearings, as supported by end covers.

Right inside the housing, the vanes can be seen radiating out from shaft to housing. The space right between rotor vanes will create pockets that help to pick up materials at the inlet.

As the rotor part of the valve rotates, the pockets’ materials get transported to the outer cell. Then the empty pockets will rotate back to the inlet for picking up the next lot of materials.

The valve consists of a drive package, which has an electric motor and a gearbox. This drive package connects to the rotor shaft by a chain drive. Some of them are directly coupled, as well.

The airlock valve’s rotor will rotate slowly and with a typical speed of around 22 RMP or less.

How to provide an airlock?

Even though the valve will not create a 100% seal, it can reduce the leakage rate greatly with its proper design. The end covers and body of the valve needs to be of premium design for withstanding different pressures. Moreover, the parks need to be precisely engineered to provide tight tolerances. Look for the raised face inside the end cover, which fits accurately into the body bore for a proper seal and alignment between housing and rotor.

Getting professional manufacturers to create a top-notch quality airlock valve is always a good call! Using the best materials and years of practice, they can create premium results in the end.